Industrial Rubber Market is expected to generate a revenue of USD 48.91 Billion by 2031, Globally, at 4.6% CAGR: Verified Market Research®

The industrial rubber market presents strong growth potential, particularly in Asia-Pacific, driven by booming automotive production, infrastructure expansion, and rising demand for high-performance synthetic rubber. However, market entrants must strategically navigate raw material price volatility and stringent environmental regulations. Companies investing in sustainable rubber technologies, cost-efficient sourcing, and regional manufacturing hubs will gain competitive advantage. Partnering with local suppliers in Asia and innovating in recyclable rubber solutions can unlock long-term growth. A focused, compliance-driven approach aligned with regional dynamics is essential for successful market penetration and expansion.

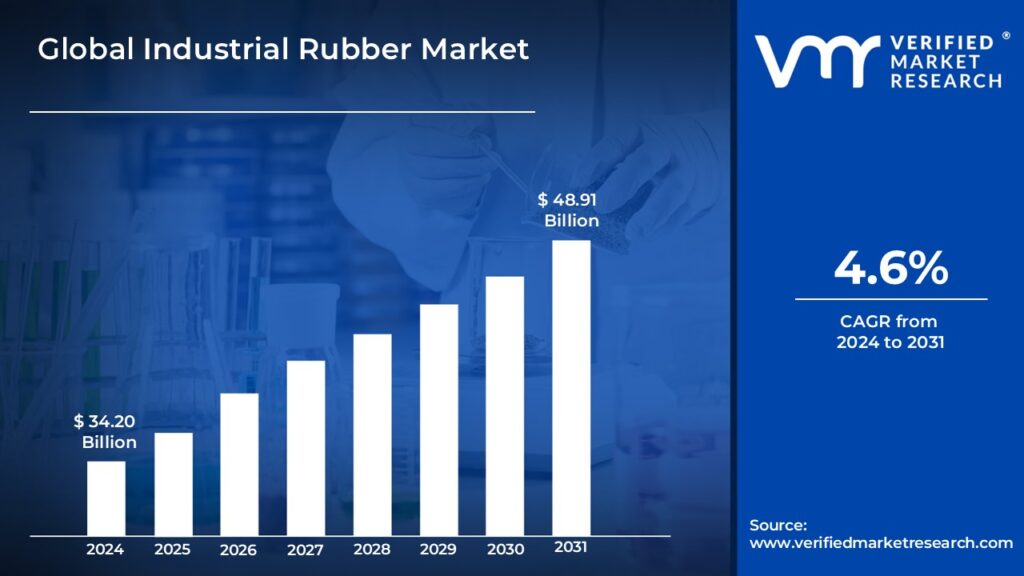

Lewes, Delaware, June 19, 2025 (GLOBE NEWSWIRE) -- The Global Industrial Rubber Market Size is projected to grow at a CAGR of 4.6% from 2024 to 2031, according to a new report published by Verified Market Research®. The report reveals that the market was valued at USD 34.20 Billion in 2024 and is expected to reach USD 48.91 Billion by the end of the forecast period.

The Industrial Rubber Market is witnessing steady growth due to its widespread application in automotive, construction, and manufacturing sectors, with rising adoption of synthetic and natural rubber in seals, belts, and hoses.

Key Highlights of the Report:

- Market Size & Forecast – In-depth analysis of current value and future projections

- Segment Analysis – Detailed study across Type, and Product.

- Regional Insights – Comprehensive coverage of North America, Europe, Asia-Pacific, and more

- Competitive Landscape – Profiles of top players and their strategic initiatives

- Technology Trends: Shift toward sustainable rubber and automation in processing

- Challenges and Risk Assessment: Evaluates ethical debates, off-target effects, and regulatory complexities.

Why This Report Matters:

This comprehensive analysis equips industry stakeholders with actionable insights into current market dynamics, key growth opportunities, and strategic challenges. It empowers decision-makers with data-backed intelligence for informed investments, procurement planning, and competitive positioning.

Who You Should Read This Report:

- B2B Industrial Buyers & Procurement Managers

- Market Research & Strategy Professionals

- Automotive & Construction Industry Stakeholders

- Rubber Manufacturers & Chemical Suppliers

- Investors & Financial Analysts Tracking the Sector

For more information or to purchase the report, please contact us at: https://www.verifiedmarketresearch.com/download-sample/?rid=26159

For more information or to purchase the report, please contact us at: https://www.verifiedmarketresearch.com/download-sample/?rid=26159

Browse in-depth TOC on “Global Industrial Rubber Market Size”

202 - Pages

126 – Tables

37 – Figures

Report Scope

| REPORT ATTRIBUTES | DETAILS |

| STUDY PERIOD | 2021-2031 |

| BASE YEAR | 2024 |

| FORECAST PERIOD | 2024-2031 |

| HISTORICAL PERIOD | 2021-2023 |

| KEY COMPANIES PROFILED | Lanxess, The Goodyear Tire & Rubber Company, Industrial Rubber & Gasket Inc., Kumho Petrochemical, Bridgestone Corp., The TSRC Corporation, JSR Corporation, Yokohama Rubber Company Ltd., Zeon Corporation, Toyo Tire & Rubber Co. Ltd., Lotte Chemical Corporation, Sinopec Corporation, LG Chem Ltd., Celanese Corporation, United Rubber Industries India Private Limited. |

| UNIT | Value (USD Billion) |

| SEGMENTS COVERED | By Type, By Product, and By Geography. |

| CUSTOMIZATION SCOPE | Free report customization (equivalent up to 4 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope |

Global Industrial Rubber Market Overview

Market Driver

Surging Automotive Production and Aftermarket Demand in Emerging Economies: One of the most prominent growth drivers for the industrial rubber market is the rapid increase in automotive production, particularly in emerging economies such as China, India, Brazil, and Mexico. Industrial rubber is an essential raw material in the automotive industry, used in a wide range of components including tires, wiper blades, suspension systems, belts, gaskets, and engine mounts. As vehicle ownership continues to grow in these regions due to rising disposable incomes and urbanization, OEMs are scaling up production capacities. Simultaneously, the aftermarket sector is thriving, driven by a growing vehicle parc and increased emphasis on maintenance and repair services. Industrial rubber's role in replacement parts such as seals, hoses, and bushings ensures consistent demand. Furthermore, strategic investments by automakers in domestic manufacturing facilities, along with supportive government policies and FDI inflows, are further accelerating rubber consumption, creating long-term opportunities for material suppliers and processing firms.

Booming Construction and Infrastructure Projects Driving High-Volume Rubber Utilization: The global construction and infrastructure sector is undergoing a phase of aggressive expansion, particularly in Asia-Pacific, the Middle East, and parts of Africa. This surge in building activities, which includes large-scale transportation projects, commercial buildings, industrial parks, and residential complexes, is significantly driving demand for industrial rubber products. Rubber is extensively used in insulation materials, vibration-damping systems, expansion joints, flooring, waterproof membranes, and protective gear for workers. Its ability to withstand high pressure, extreme temperatures, and mechanical stress makes it an ideal material in modern construction environments. For instance, in bridge and highway development, rubber bearings and shock absorbers are standard. Countries such as China (through the Belt and Road Initiative), India (Smart Cities Mission), and Saudi Arabia (Vision 2030) are injecting billions of dollars into infrastructure, directly contributing to volume growth in industrial rubber procurement. Moreover, the green building trend is pushing for advanced rubber materials with low VOCs, spurring innovation and premium-grade product demand.

Technological Advancements in Synthetic Rubber Enhancing Industrial Applications: Another major growth catalyst for the industrial rubber market is the increasing adoption and continuous innovation in synthetic rubber compounds. Compared to natural rubber, synthetic variants like Nitrile Butadiene Rubber (NBR), Ethylene Propylene Diene Monomer (EPDM), Styrene-Butadiene Rubber (SBR), and Fluoroelastomers offer superior chemical resistance, durability, and heat stability—making them ideal for heavy-duty industrial environments such as oil & gas, mining, marine, aerospace, and electronics manufacturing. These industries demand customized rubber formulations that can perform under intense pressure, corrosive exposure, and varying temperatures. Recent advancements in polymer engineering and rubber compounding technologies have enabled the development of lightweight, high-performance, and environmentally compliant rubber materials. Furthermore, increased focus on sustainability and recyclability is pushing R&D towards bio-based and green synthetic rubbers. As industries look to minimize downtime and optimize performance, the shift toward advanced synthetic rubbers are expected to gain momentum, positioning them as a long-term growth engine for the market.

To Purchase a Comprehensive Report Analysis: https://www.verifiedmarketresearch.com/select-licence/?rid=26159

To Purchase a Comprehensive Report Analysis: https://www.verifiedmarketresearch.com/select-licence/?rid=26159

Market Restraint

Price Volatility of Crude Oil-Derived Raw Materials Affecting Profit Margins: A critical restraint affecting the industrial rubber market is the high sensitivity of synthetic rubber pricing to crude oil fluctuations. Synthetic rubbers such as SBR, NBR, and EPDM are derivatives of petrochemical feedstock like butadiene, ethylene, and styrene. With crude oil being a globally traded and geopolitically sensitive commodity, its price volatility directly impacts raw material costs, leading to unpredictable manufacturing expenses for rubber processors. This creates budgeting challenges, hinders pricing stability, and discourages long-term procurement contracts. SMEs in the rubber supply chain are particularly vulnerable, as they lack the scale to hedge against commodity risks or absorb cost shocks. Additionally, price-sensitive end-use industries like automotive and construction may delay orders or substitute materials during periods of high cost inflation, negatively impacting sales volumes. The lack of affordable alternatives and dependence on global petrochemical supply chains adds another layer of risk, making cost management a persistent concern in market scalability.

Increasing Stringency of Environmental and Occupational Safety Regulations: The manufacturing, processing, and disposal of industrial rubber products are increasingly coming under the regulatory scanner due to concerns around chemical emissions, air and water pollution, and worker safety. Regulatory agencies such as the U.S. Environmental Protection Agency (EPA), European Chemicals Agency (ECHA), and national bodies across Asia are enforcing stricter compliance norms under frameworks like REACH and OSHA. Key areas of concern include the use of hazardous vulcanization agents, carbon black emissions, and waste disposal challenges. Non-compliance can result in operational shutdowns, heavy fines, and reputational damage. Additionally, manufacturers are being pressured to transition toward sustainable and green rubber formulations, which often involve higher R&D costs and retooling of existing production facilities. These changes disproportionately affect small and medium rubber processors with limited financial resources, potentially leading to industry consolidation. Thus, regulatory complexity acts as a strong deterrent for new entrants and a strategic risk for established players.

Limited Rubber Recycling Infrastructure and Disposal Challenges: Despite rising awareness of circular economy practices, rubber recycling remains an underdeveloped domain in many regions. Unlike metals or plastics, rubber—especially vulcanized rubber—is difficult to recycle due to its cross-linked polymer structure. This presents a major waste management challenge for industries and governments alike. The accumulation of used rubber components, particularly industrial-grade tires, seals, belts, and mats, contributes significantly to environmental pollution. In many regions, incineration and landfill disposal remain the primary methods, both of which raise sustainability concerns. The lack of standardized recycling infrastructure, regulatory incentives, and economically viable recycling technologies hampers the adoption of eco-friendly rubber usage models. Additionally, recycled rubber often fails to meet the stringent performance criteria required in industrial applications, limiting its commercial viability. This ongoing disposal dilemma not only adds to operating costs but also creates long-term environmental liabilities for manufacturers and industrial users.

Geographical Dominance: Asia-Pacific holds the dominant share in the industrial rubber market, driven by massive automotive production, rapid industrialization, and large-scale infrastructure development across China, India, Japan, and Southeast Asia. The region’s cost-effective labor, abundant raw material availability, and expanding manufacturing base attract global investors. Government initiatives promoting domestic production, coupled with high consumption from construction and transportation sectors, further solidify Asia-Pacific's leadership in global rubber demand.

Key Players

The “Global Industrial Rubber Market” study report will provide a valuable insight with an emphasis on the global market. The major players in the market are Lanxess, The Goodyear Tire & Rubber Company, Industrial Rubber & Gasket Inc., Kumho Petrochemical, Bridgestone Corp., The TSRC Corporation, JSR Corporation, Yokohama Rubber Company Ltd., Zeon Corporation, Toyo Tire & Rubber Co. Ltd., Lotte Chemical Corporation, Sinopec Corporation, LG Chem Ltd., Celanese Corporation, United Rubber Industries India Private Limited.

Industrial Rubber Market Segment Analysis

Based on the research, Verified Market Research has segmented the global market into Type, Product, and Geography.

-

Industrial Rubber Market, by Type

- Natural Rubber

- Synthetic Rubber

- Styrene-Butadiene

- Polybutadiene

- Polyisoprene

- Ethylene Propylene Diene Monomer

- Nitrile

- Chloroprene

- Silicone

- Fluor Elastomers

-

Industrial Rubber Market, by Product

- Tires

- Conveyor Belts

- Hoses

- Seals & Gaskets

- Roofing Membranes

- Insulation

- Molded Rubber Products

- Footwear

- Others

-

Industrial Rubber Market, by Geography

-

North America

- U.S

- Canada

- Mexico

-

Europe

- Germany

- France

- U.K

- Rest of Europe

-

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

-

ROW

- Middle East & Africa

- Latin America

-

North America

Browse Related Reports:

Global High Dispersible Silica Market Size By Form (Micropearl and Granular), By Application (Tires, Industrial Rubber Products and Others), By Geography, And Forecast

India Liquid Silicon Rubber Market Size By Product Type (Food Grade Liquid Silicone Rubber, Medical Grade Liquid Silicone Rubber, Industrial Grade Liquid Silicone Rubber), By Application (Automotive, Medical Devices, Electronics), By Distribution Channel (Direct Sales, Distributors, Online Sales), By Geography, And Forecast

Global Technically Specified Rubber Market Size By Rubber Type (Natural Rubber, Synthetic Rubber), By Application (Sealing & Gaskets, Hoses & Tubing), By End-User Industry (Automotive, Aerospace), By Geography, And Forecast

Global Soft Robotic Gripper Market Size By Product (Parallel, Angular), By Material Type (Silicone, Rubber), By Actuation Method (Pneumatic Actuation, Electromechanical Actuation), By Application (Pick And Place, Assembly), By End User (Food And Beverages, Manufacturing), By Geography, And Forecast

Top 7 Hydrogenated Nitrile Butadiene Rubber Manufacturers resisting heat effectively

Visualize Industrial Rubber Market using Verified Market Intelligence -:

Verified Market Intelligence is our BI Enabled Platform for narrative storytelling in this market. VMI offers in-depth forecasted trends and accurate Insights on over 20,000+ emerging & niche markets, helping you make critical revenue-impacting decisions for a brilliant future.

VMI provides a holistic overview and global competitive landscape with respect to Region, Country, Segment, and Key players of your market. Present your Market Report & findings with an inbuilt presentation feature saving over 70% of your time and resources for Investor, Sales & Marketing, R&D, and Product Development pitches. VMI enables data delivery In Excel and Interactive PDF formats with over 15+ Key Market Indicators for your market.

About Us

Verified Market Research® stands at the forefront as a global leader in Research and Consulting, offering unparalleled analytical research solutions that empower organizations with the insights needed for critical business decisions. Celebrating 10+ years of service, VMR has been instrumental in providing founders and companies with precise, up-to-date research data.

With a team of 500+ Analysts and subject matter experts, VMR leverages internationally recognized research methodologies for data collection and analyses, covering over 15,000 high impact and niche markets. This robust team ensures data integrity and offers insights that are both informative and actionable, tailored to the strategic needs of businesses across various industries.

VMR's domain expertise is recognized across 14 key industries, including Semiconductor & Electronics, Healthcare & Pharmaceuticals, Energy, Technology, Automobiles, Defense, Mining, Manufacturing, Retail, and Agriculture & Food. In-depth market analysis cover over 52 countries, with advanced data collection methods and sophisticated research techniques being utilized. This approach allows for actionable insights to be furnished by seasoned analysts, equipping clients with the essential knowledge necessary for critical revenue decisions across these varied and vital industries.

Verified Market Research® is also a member of ESOMAR, an organization renowned for setting the benchmark in ethical and professional standards in market research. This affiliation highlights VMR's dedication to conducting research with integrity and reliability, ensuring that the insights offered are not only valuable but also ethically sourced and respected worldwide.

Mr. Edwyne Fernandes Verified Market Research® US: +1 (650)-781-4080 US Toll Free: +1 (800)-782-1768 Email: sales@verifiedmarketresearch.com Web: https://www.verifiedmarketresearch.com/ Follow Us: LinkedIn | Twitter | Threads | Instagram | Facebook SOURCE – Verified Market Research®

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.